Paul and I had a good chat about donor vehicles and came up with one manufacturer that resisted the FWD trend and whose cars were fairly affordable: BMW (Break My Wallet). I was able to find a 1995 318i Cabriolet that was being parted out by a young fellow. By the time I got to it it was pretty much gone, but the suspension was intact and that’s what we needed. I bought it and had it towed home.

The engine and automatic transmission were still in the car but we wouldn’t using them. Let the dismantling begin.

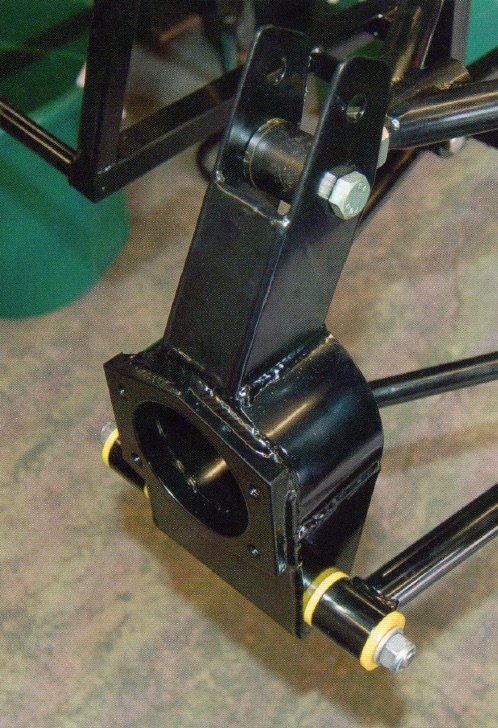

Here is one of the rear hubs, it is a large steel casting that does a lot of things. It holds the bearing that the end of the half shaft passes through (outside the CV joint) to drive the rear wheel. It also mounts the brake caliper, the control arms and that curved piece ties into the car frame to allow the rear suspension to travel up and down but not front to back.

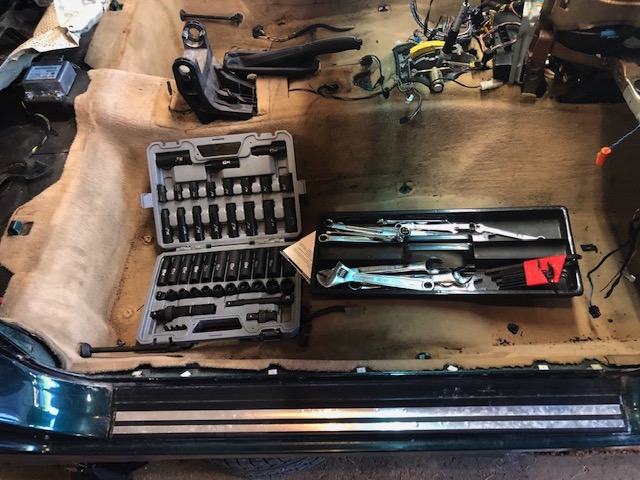

I swear that BMW and Canadian Tire are in cahoots. Every time I go to take something apart I need another tool or a different type of socket. This is the 12 point 30mm nut holding the hub on, beside it is the beautiful new set of sockets. At least the hub is off.

Oh, and those are Torx head bolts (of course) holding the half shaft onto the differential. Another trip to CTC and we are in business. I got to make use of my favorite new tool – the impact wrench!

Bye Bye Bimmer. With all the useful parts left behind, the BMW is unceremoniously dragged from the garage and sent off to the recycle yard.

Now that the rear hubs are free of the half shafts we need to take them apart. This involves pressing the bearings out of the housing. This could be done by a local garage but they would spend at least an hour and a half doing it and that would cost a couple hundred dollars.

For about the same money, I can buy a 10 ton hydraulic press (on sale at Canadian Tire!) to do the job. As a bonus, I will have it to do all kinds of other jobs like pressing in the new bearings down the road! I have been trolling the Canadian Tire and Princess Auto web sites looking for tools I will need to go on sale. It is called a Locost after all!

The big snap ring holds the bearing in. Once it is removed the press can be used to push the bearing out. This is a bit tricky because of the casting shape. It takes a few tons force to get it out.

I decided to try to cut the bearing holder from hub. The plan is to incorporate them into the new fabricated rear hubs. The rest of the BMW casting will be discarded. The standard rear hub from the book will be modified to fit the E36 components.

This is a slow, noisy, dirty job but it has to be done and I couldn’t talk Tom into doing it. Several abrasive disk later the job is completed. I looked like a coal miner after a 12 hour shift.

More work with the angle grinder to get the bearing holder basically round. Tom will be taking these to New Brunswick to turn them on his lathe. He will use an inside chuck so he can cleanup the outside and flatten the bottom surface of the casting which has a slight concave dish to it.

![]()