This post covers a time period of about two weeks from late April to mid May.

Very early in the build you are tasked with building the front frame for the Locost. By this time I have cut all the lower frame tubes and made some angle cuts successfully. I am feeling pretty good about my fabricating skills, however…

…this piece requires compound angles to be cut and a jig to be made to facilitate assembly. I really struggled to get this right, I made it twice before moving on.

What they don’t stress in the book is the importance of front frame. Four of the front suspension brackets will get welded onto it. If it is not perfect there will be problems getting the brackets aligned. Fortunately, nothing is fully welded by the time you get to that point so things can (and will) be adjusted.

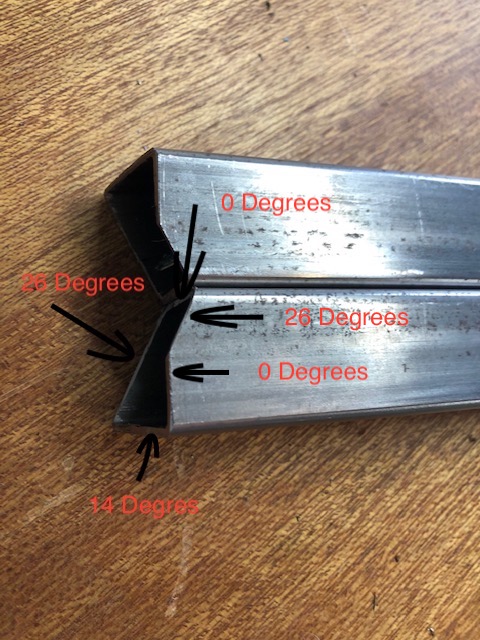

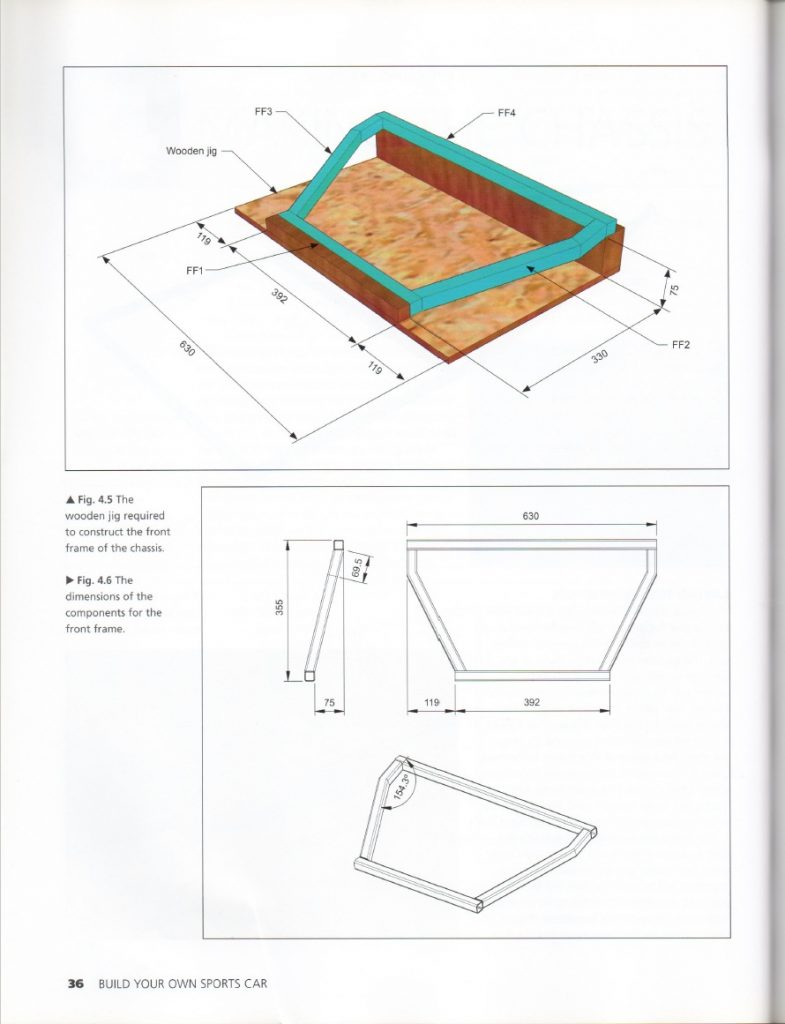

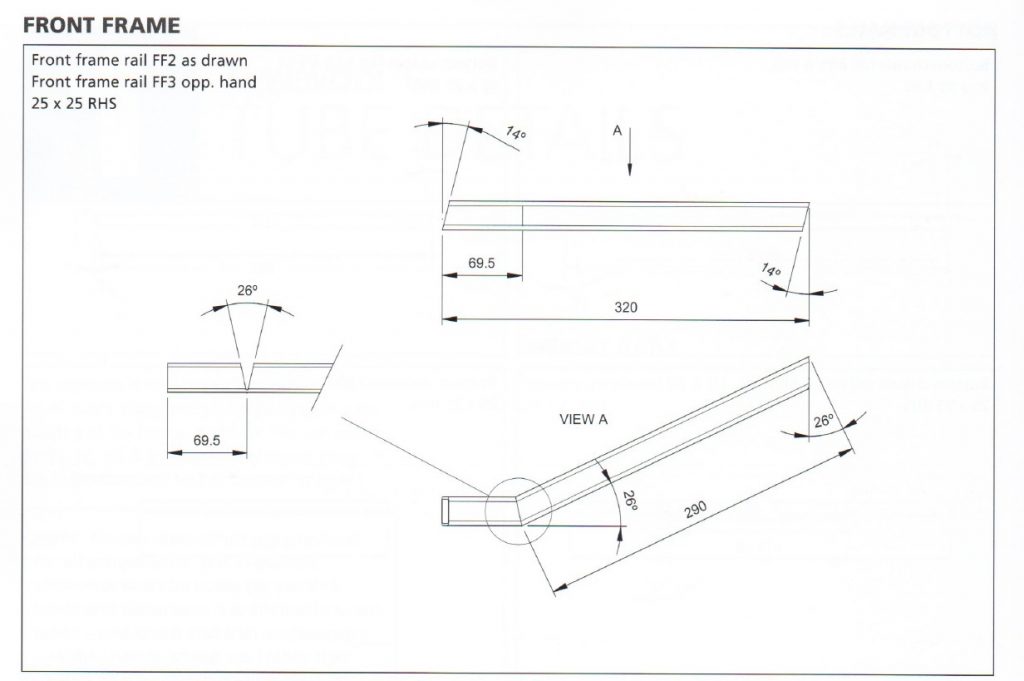

This is the detail drawing that you work from. Where the drawing says take a 26 degree wedge out of the tube I opted to cut the tube off at 13 degrees on each side and tack it back together to from the angle.

Cutting compound angles: After the first angle is cut, rotate the tubes 90 degrees. In this case one is rotated left one right as they are a handed pair. The second cut trims the tube end at the second angle leaving the tubes with two faces that need to be cut/ground/filed to match the angles of the opposite sides. EasyPeezy…

This was my first attempt at making the jig on an old piece of MDF.

Cutting, clamping and tacking the tubes together. At this point I realized that it would be far easier if the two angled arms were tacked together before fitting. I won’t make that mistake again, there are plenty of other mistakes to be made.

I persisted, for better or worse, got things lined up and tacked the frame together.

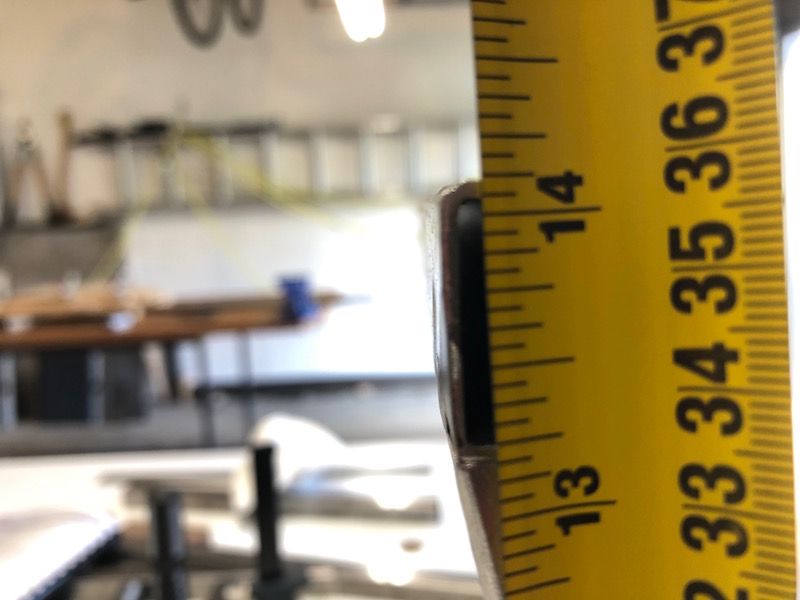

I put the frame in position on the bench but the top tube isn’t level. I checked my jig and it was definitely not flat contributing to the issue – live and learn.

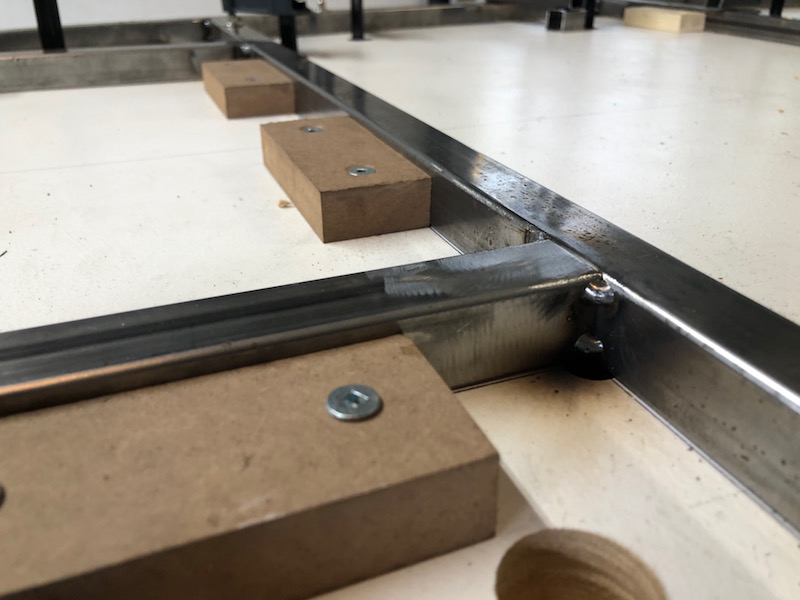

I rebuilt the jig using the top of the assembly table as the base, I know that’s flat. I also tacked the dog legs before fitting them on the jig. This gave a satisfactory result.

The top tube is now level and things look good. The frame gets height! Time to tack everything together.

Typical joints on the frame. Every tube is clamped to the table in two locations and all the joints are nice and tight. I drilled relief holes in the MDF top at all the joints so I could tack close to the bench top without causing a fire. My tacking is way better than my welding!

![]()