Ok, so a welding cart is not really a vehicle but it does have a frame and wheels so it is a step in the Locost direction.

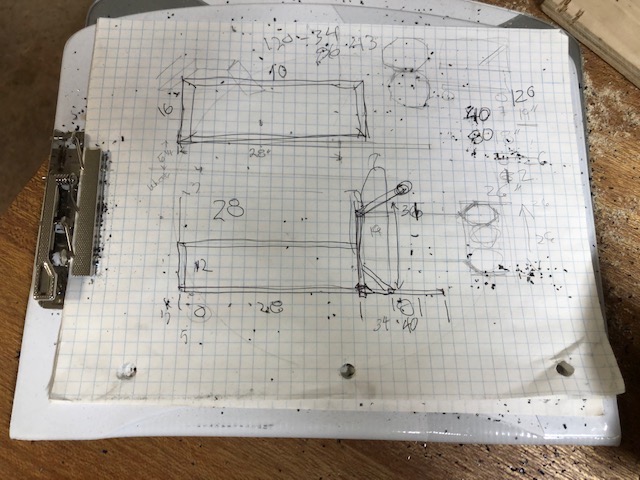

It’s good to start with a plan. In this case I have gone with PAD (Pencil Aided Design) for the welding cart rather than CAD. I will have to go digital sooner or later…

Cutting components for the frame with the chop saw (two at a time) to ensure matching pieces are identical. I am using 1″ square 16 ga. tubing – the same material used in the Locost frame.

Bottom frame welded together. Keeping things flat is more difficult then getting them square. A steel welding table to clamp the tubes on would be a great help.

Starting to look like the plan!

Progress.

The Good, The Bad and the Lumpy.

Something to attach the wheels to.

Stitching the bottom shelf to the frame.

Checking the fit.

Wheel detail – nice weld!

Capping off all the open tubes, a lot of angle grinder work required.

The tank holder slips over the two horns to secure the tank.

Into the basement paint shop for primer and paint. This was a bit of a disaster as Tremco rust paint is oil based and really smells up the house. Battle ship grey was applied in the garage despite the cool weather.

Ready to roll.

![]()