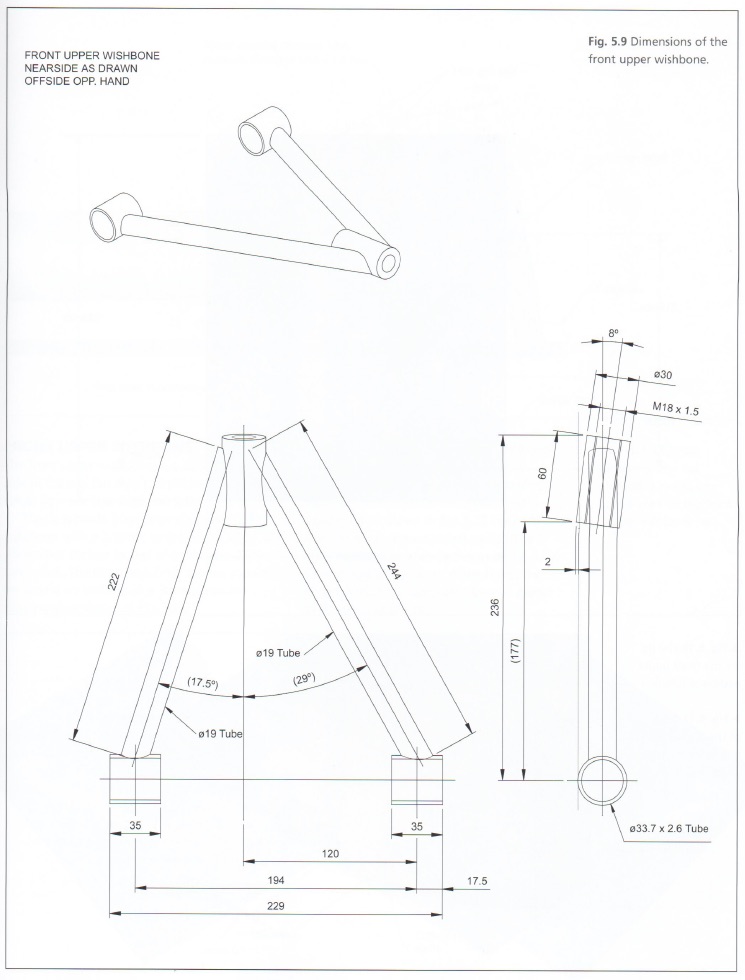

In the tradition of saving the worst till last, I give you the front upper control arms.

The issue with these control arms is that the threaded tube that holds the upper ball joint is offset 8 degrees. I will need to do some “innovative lathe work” as my tube notching attachment is designed to make notches that have zero degrees offset. This design also means that we need a more complicated jig as the left and right hand pieces are unique cannot be flopped from side to side (because of the offset).

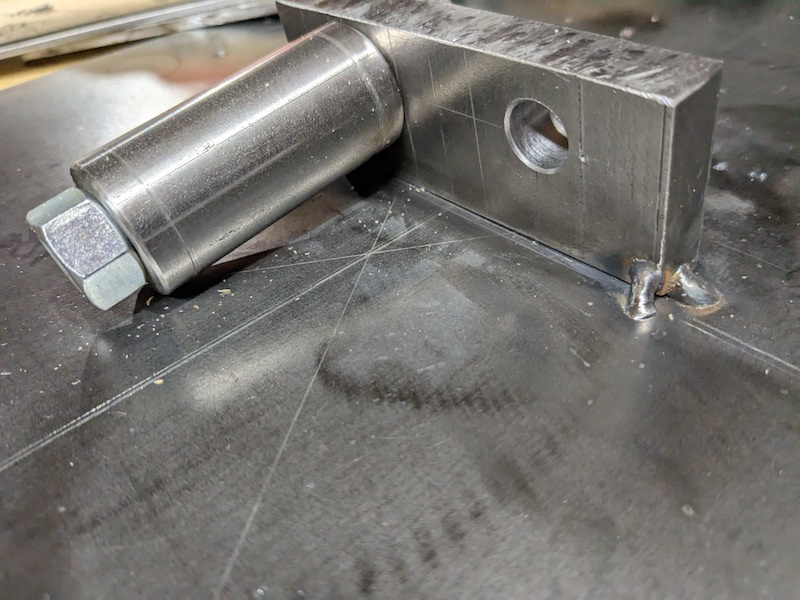

This jig is similar to the one used for the rear upper control arms with a couple exceptions. We are using 1/2″ plate and need to cut 8 degrees off the edge of the upright so that the threaded ball joint holders are not held horizontal for assembly. Instead of making two jigs (right and left) we can use one with 2 positions for the threaded ball joint holder. Finally, we trim the plate to length.

Here is the single jig that can locate a ball joint holder in one of 2 positions at the required 8 degrees off the horizontal. Now, how to cut the 3/4″ tubes to connect to it?

My solution was to cut a wedge to use in the tube notcher to create the offset. The wedge is not 8 degrees because the angle iron faces are at 45 degrees so some trigonometry was used to come up with the right angle (11.3 degrees I think). The right image shows how the wedge is used and the precarious job of clamping the tube in place.

Cutting is very slow going and again the cut bottoms out in the hole saw and needs to be cleared before finishing. The results are good but the process is a bit scary.

Now we can use the jig to set up each of the control arms and tack weld them. That is a lot of work for 8 degrees!

![]()