Before you can join metal in a useful way you have to cut it into appropriate pieces. I started using a wood cutting chop saw with an abrasive blade installed. Although it works, this method is a slow and noisy plus it produces a lot of sparks, smoke and heat – things I would rather avoid.

The alternatives were to acquire a steel cutting band saw or a cold cut chop saw. Band saws are quiet and a bit slow, chop saws are noisy and fast. I looked at both and opted for the chop saw. This is a very affordable Evolution Rage 2.

It comes with a 14 inch blade that can cut steel, aluminum, wood etc. Cold cut saws have carbide teeth that cut through metal (very quickly) rather than using friction to burn through it. The result is very few sparks, a clean cut and very little heat build up. The small chips of metal (shrapnel) that are cut from the material material wind up scattered about.

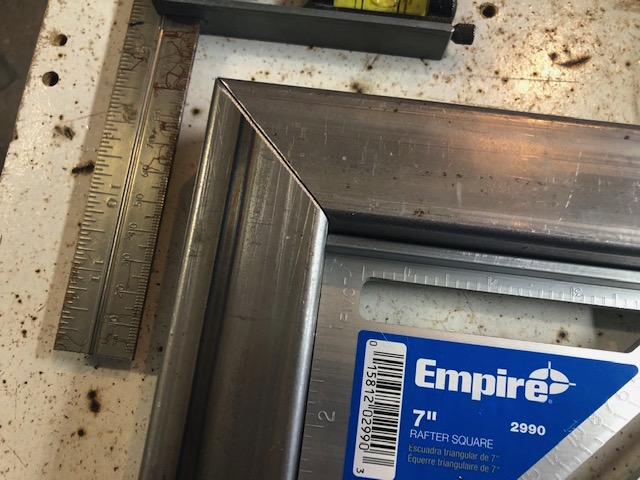

The result of a couple 45 degree cuts looks really good.

![]()