Welding is one of the skills required to build a Locost. There are several types of welding equipment that can be used: MIG, TIG, stick or gas, the choice is yours. Most builders choose MIG as it is apparently the easiest to learn, we’ll see about that. MIG welding has been described as “the hot glue gun” of metal joinery! This should be fun!

I started welding with a Mastercraft transformer type welder. I had zero welding experience but watched any instructional videos I could find on YouTube to get an idea of what to do. This is a 120 volt machine with four voltage settings and variable wire feed speed, no combination of which seemed to work for me! No matter what I tried I couldn’t seem to make a descent bead.

This was my welding shop. I was using flux core wire so no shielding gas was required. Occasionally the bench (rickety sawhorses and particle core sheet) would catch fire! Welding generates a lot of heat with the arc/weld pool reaching several thousand degrees C and wood igniting at less than 200 – go figure.

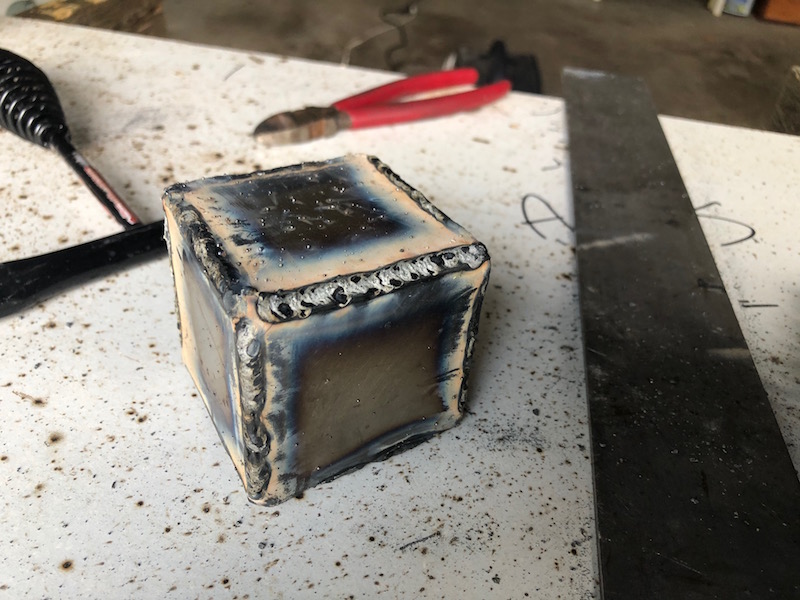

Early attempts, these are really bad.

One problem I had was not being able to see where my weld was going to start until the arc was struck! For an inexperienced welder this is an issue. I upgraded to an auto shade helmet. The shield is clear (well nearly clear) and darkens instantly as the arc is struck. Voila, you can see your work before the arc and then you can see the weld pool after. This was a game changer, allowing me to start the weld where I wanted. Unfortunately it did didn’t improve the quality of my welds.

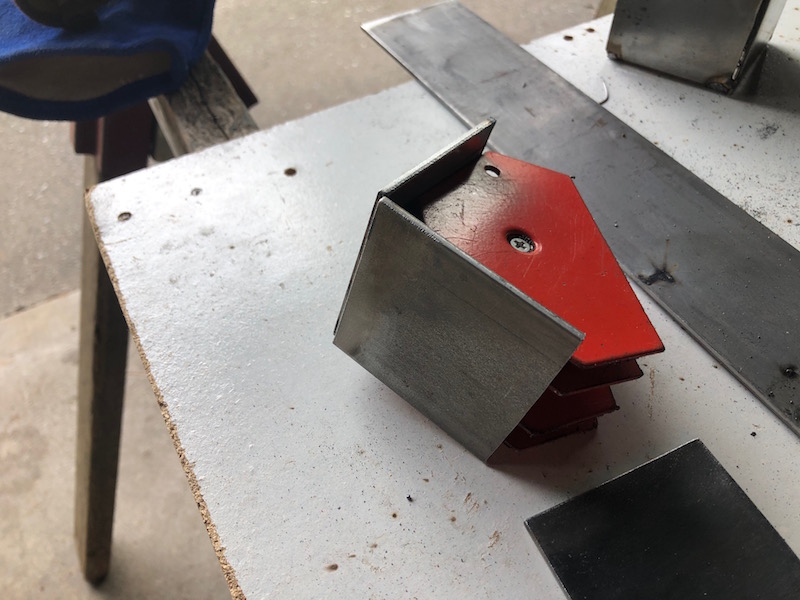

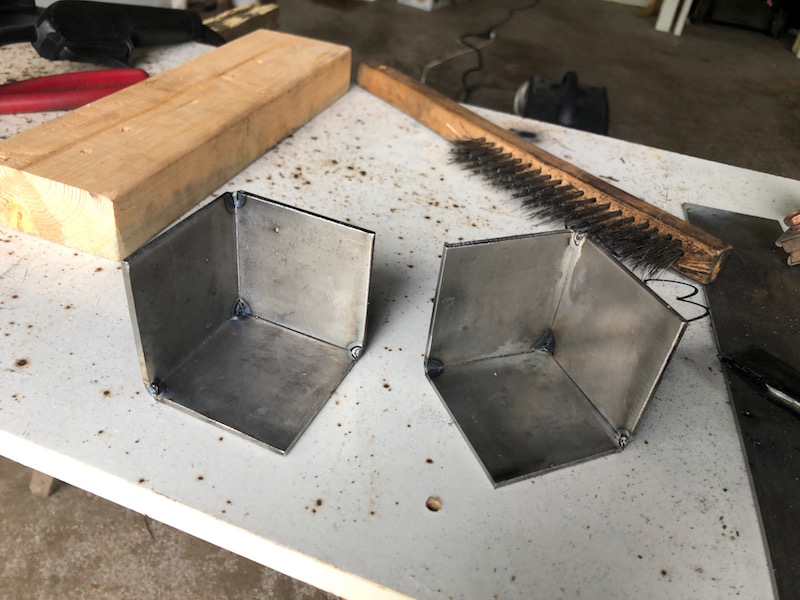

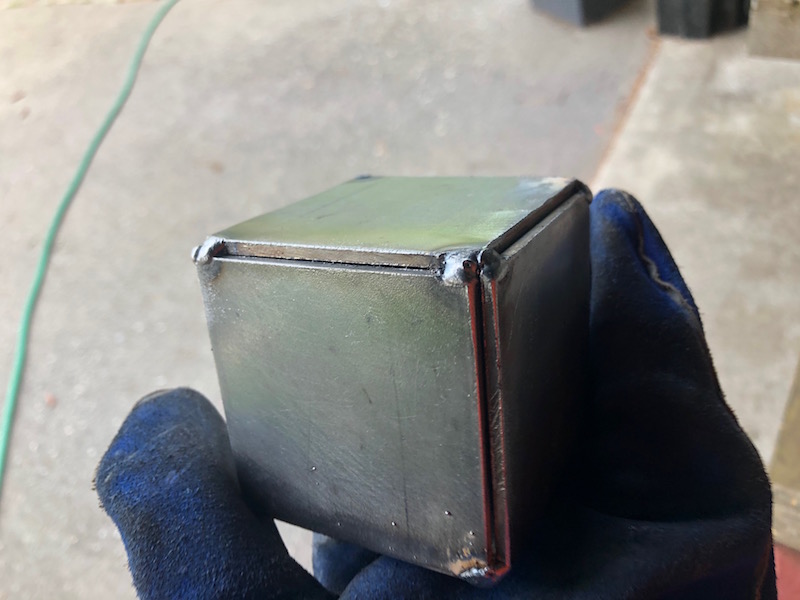

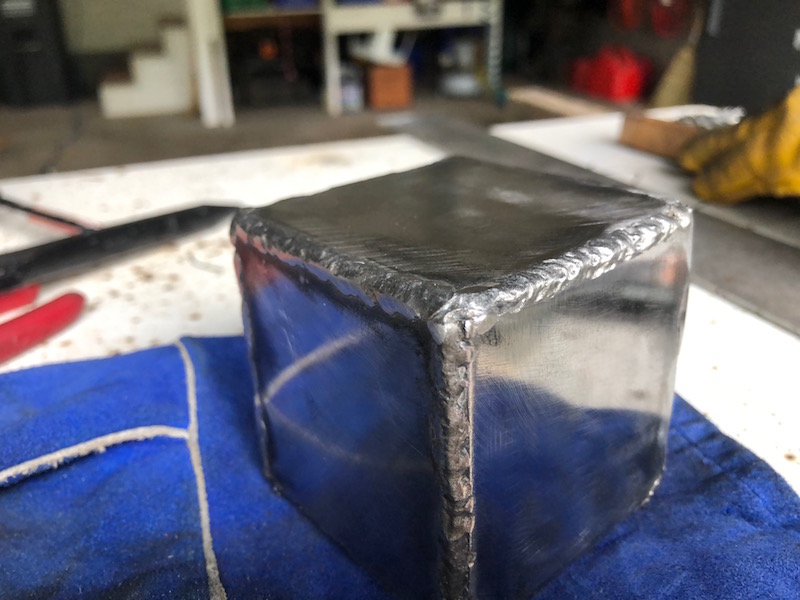

To get more practice welding I started to make steel cubes, cutting squares from a piece of 2.5 inch wide 1/8th plate. This is good practice since you need to cut and assemble pieces rather than just laying a bead on a flat piece of steel. You also get practice using an angle grinder – a key piece of equipment in the build.

The complete paperweight making process in pictures.

After all this practice I was still not getting consistent acceptable welds. I began to suspect that the problem was not entirely mine so I started to look for a better welder that wouldn’t break the bank.

![]()