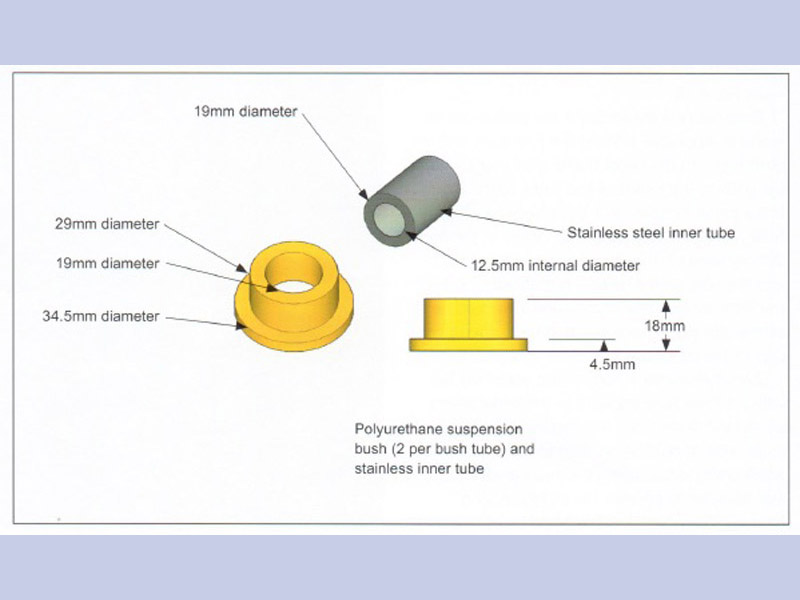

Time to make bushings for all of those control arms.

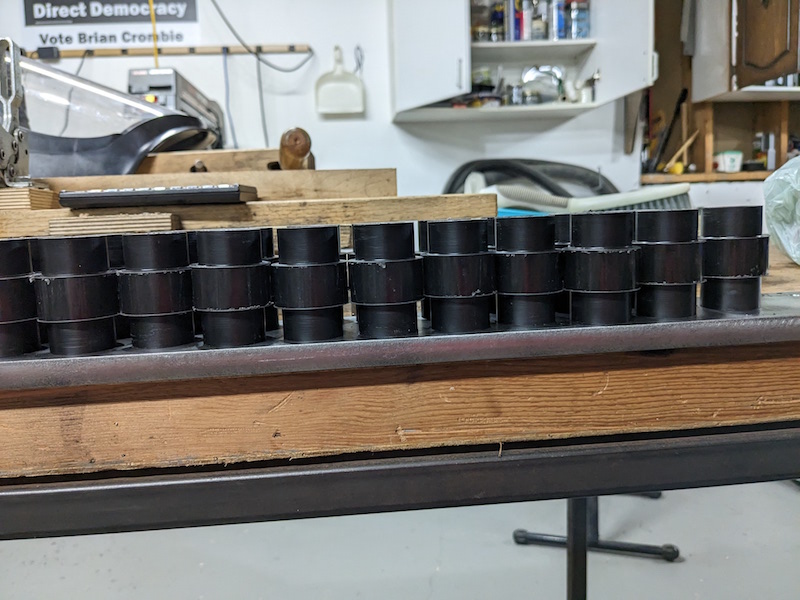

Here are the bushings required for the car, they are split so two are required for each bushing tube. Here are all the control arms with bushing tubes attached, we are going to need a lot of bushings!

The book calls for Polyurethane material but it is difficult to machine at the hardness required. Polyurethane could be mixed in liquid form and pored into bushing shaped molds but since I don’t have any molds we will be substituting. Delrin is a harder plastic that is easier to machine, it’s self lubricating and is available as round rod. That’s what I’ll be using.

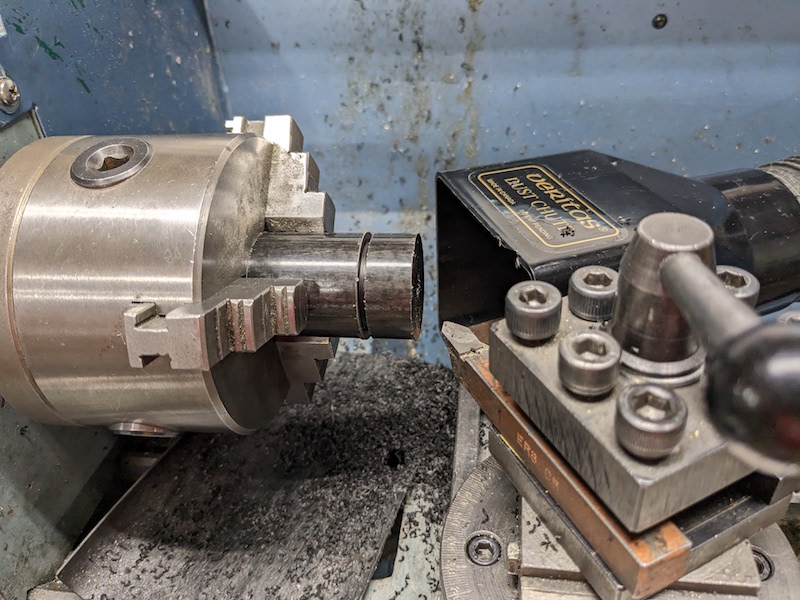

I started by cutting the rod into pieces using a radial arm saw. Each piece is long enough to make 2 bushings. I then center drilled them and faced the ends in the lathe.

Next I used a parting tool to to cut the relief that defines the shoulder of one bushing and turned that end down to size.

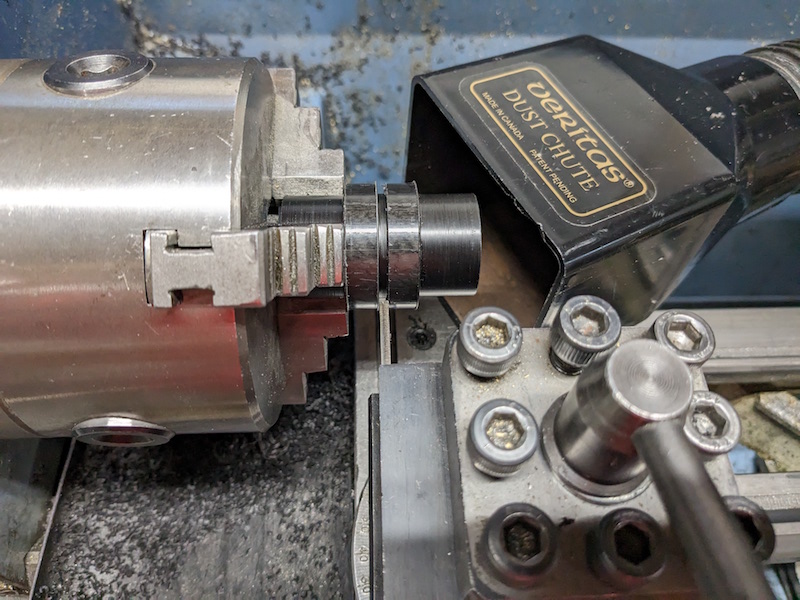

Now I could flip each blank around use the parting tool to define the other bushing shoulder and turn the end other down.

The parting tool marks the cutoff point for the 2 bushing halves but before splitting them I beveled the corners to make it easier to press them into the bushing tubes. There you have it a bushel of bushings.

![]()